Double side labeling machine

Specification of this Double side labeling machine

Double side labeling machine apply to alcohol, medicine, beverages, chemicals, pesticides and other self-adhesive labeling square/flat/round bottles. Host design labeling machines using imported and domestic advanced technology, and to improve and perfect solution for general labeling of domestic instability, optical fiber by computer control, synchronization track, the standard by a servo motor control, automatic detection size of objects and labels are affixed, and automatically controlled by microcomputer mode, large LCD touch panel, display and memory device containing dozens of groups, is modern and advanced equipment, electric mechanical integration, simple, accurate labeling, reliable performance, power, no noise. Sticker labeling machine is easy to clean, not moldy, after labeling beautiful, strong, will not fall off on their own production efficiency.Features:

Double side labeling machine apply to alcohol, medicine, beverages, chemicals, pesticides and other self-adhesive labeling square/flat/round bottles. Host design labeling machines using imported and domestic advanced technology, and to improve and perfect solution for general labeling of domestic instability, optical fiber by computer control, synchronization track, the standard by a servo motor control, automatic detection size of objects and labels are affixed, and automatically controlled by microcomputer mode, large LCD touch panel, display and memory device containing dozens of groups, is modern and advanced equipment, electric mechanical integration, simple, accurate labeling, reliable performance, power, no noise. Sticker labeling machine is easy to clean, not moldy, after labeling beautiful, strong, will not fall off on their own production efficiency.Features:

- Adopt imported electromagnetic clutch with best accuracy.

- The machine shell adopts high class aluminum alloy anodic treatment, with long life span service.

- Adopt famous factory electric motor to ensure high load and ling period operation.

- All parts and standard components are carefully made of stainless steel.

- With PLC control panel, the operation is simple and convenient, the function is stable.

- Imported label inspection optical coupler can ensure high precision.

Workflow:

Bottle distributing—Correcting—Pressing—Labeling—Reinforcing—Finish

- Fix the label roll on the machine according to the graphical representation, adjust the height of each part

- Check if all the position of the labels are correct.

- Adjust the distance between the two rails, the distance between the brush and the conveyor, make sure the distance is suitablefor the product to pass

- Turn on the power switch, turn on the optoelectronic switch.

- Turn on switch of the motor and label sending device, debug labeling, if there are any abnormal, get rid of them.

- Adjust the labeling position

- Ensure the test is ok, then operating the machine normally.

About Packing:

To ensure our service quality, we will execute the following packaging standards in delivery:

- All machines before shipping should be tested pass, wiped up and clean, wrapped by stretch film to protect it from moist. The precision part need to be flexible package.

2.All machines will be packed in wooden case. The exported products use plywood case to pack. The foot margin of equipment fixed tightly to make the machine can experience loading and uploading, the upward mark will be posted on the wooden case.

Parameters of this Double side labeling machine

| Model Name | BTS-150D |

| Operating direction | Right/Left |

| Production(Bottle/Min) | 30-160(subject to the size of objects and labels |

| Conveyor speed(Meter/min) | 40 |

| Labeling accuracy | 1.0mm |

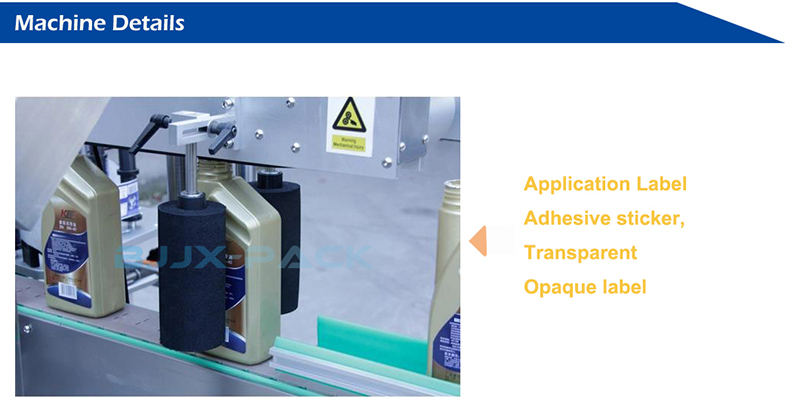

| Application label | Adhesive sticker, transparent or opaque label |

| Inner diameter of label roll | 76mm |

| Outer diameter of label roll | 350mm(MAX) |

| Application size of label | Width 15-140mm, length 15-300mm |

| Application size of bottle | Can customized as label objects |

| Weight(Kg) | 300 |

| Power(W) | 1KW |

| Voltage | AC110V/220V 50/60Hz |

| Machine Size(mm) | 2400(L)1350(W) 1500(H)mm |

Pictures of this Double side labeling machine

Write your message here and send it to us